Lock housing plays a vital role in securing locks and ensuring their sturdiness. Splendid lock housing guarantees protection and capability for residential, industrial, or business use. If you’re a consumer, knowing the manufacturing procedure and how to pick the proper product is vital. This guide will walk you through the fundamentals of lock mechanism casing production, key insights, and valuable tips for getting.

What Is Lock Housing?

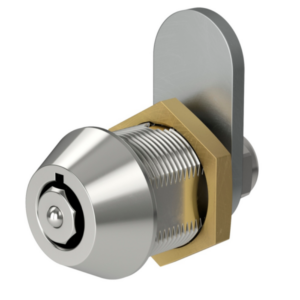

Lock housing is the outer casing that protects a lock’s inner components. It provides structural support and shields the lock’s mechanism from harm. Metal lock components are crafted from stainless steel, brass, aluminum, or zinc alloy. Their durability depends on the manufacturing technique and the best materials used.

The Manufacturing Process of Lock Housing

Security lock enclosure production entails several steps to ensure durability, precision, and safety. Let’s explore those steps in simple phrases:

Material Selection

Manufacturers begin using choosing tremendous substances. The material should be robust, rust-resistant, and suitable for the lock’s reason. For example:

Stainless metal is suitable for outside locks because it resists corrosion.

Brass is famous for its clean end and durability.

Design and Molding

Next, producers create designs based on the lock’s form. Molds are prepared to shape the housing, and advanced computer software ensures specific designs.

Casting or Forging

The selected fabric is heated and poured into molds (casting) or shaped using high pressure (forging). This step creates the basic shape of the durable lock shells.

Machining

After forming, the housing is refined by machining. Machines cut, drill, and varnish it to fulfill exact specifications. This step ensures the housing fits flawlessly with the lock mechanism.

Finishing

The housing undergoes floor remedies, like sprucing, painting, or plating. These remedies enhance the housing’s appearance and protect it from rust or put on.

Quality Control

Every lock housing is inspected for electricity, dimensions, and end. Testing ensures the product meets safety and sturdiness requirements.

Key Insights for Buyers

If you are planning to shop for lock body materials, keep these key insights in mind:

Understand Your Needs: Different locks require specific housings. Identify where and how the lock may be used. For instance:

High-safety locks need more excellent, sturdy housing.

Weatherproof locks require corrosion-resistant substances.

Check Material Quality: Always choose a house crafted from durable substances. Poor-nice materials can weaken the lock over the years.

Look for Certifications: Reliable producers observe safety requirements and provide certifications. These ensure the lock housing is tested and trustworthy.

Consider Customization: If you need protective lock covers for a unique purpose, ask about customization. Many manufacturers offer custom designs to fit your requirements.

Compare Suppliers: Research and examine exceptional suppliers. Look for agencies with an excellent reputation, competitive fees, and remarkable customer support.

Tips for Buying Lock Housing

Ask About Production Techniques

Modern manufacturing strategies ensure excellent durability and precision. Look for providers that use advanced methods, such as CNC machining or automated testing.

Order Samples

Request samples before placing a large order. Check the high quality, size, and finish to ensure they meet your requirements.

Inquire About Maintenance

Some lock housings require ordinary cleaning or coating to maintain appearance and overall performance. Ask for protection tips when purchasing.

What Is the Top and Trusted Site for Lock Housing Manufacturing?

Choosing the proper manufacturer is critical when locating an excellent lock casing manufacturer. A reliable company guarantees durable, precise, and nicely made lock additives. Junying Metal Manufacturing Co. stands proud as a depended-on call in the industry for groups and individuals looking for excellence.

Why Choose Junying Metal Manufacturing Co., Limited?

Decades of Experience

Junying Metal Manufacturing Co., Limited has been a frontrunner in lock accent manufacturing for decades. With years of expertise, they understand how to supply merchandise that meets the highest requirements.

Wide Range of Products

They provide a whole variety of lock accessories, along with:

- SFIC cores and IC cores

- Custom SFIC locks

- Lock cylinders and mortise cylinders.

- Push-lock housings and push-lock springs.

- Cam lock housings, nuts, latches, and washers

- Door lock elements and clean essential additives

With such variety, they cater to numerous protection desires for homes, workplaces, and business setups.

FAQs About Lock Housing

What materials are exceptional for lock housing?

Stainless metal and brass are excellent picks. Stainless metal resists rust, while brass is long-lasting and has a clean finish.

Can lock housing be custom-designed?

Yes, many producers offer custom designs. You can get lock housing tailor-made to particular shapes, sizes, or functions.

How do I ensure the satisfactory quality of lock housing?

Check for certifications, request samples, and assess the provider’s popularity. Constantly affirm the materials used.

Final Thoughts

Lock housing is an essential issue for an easy and helpful lock. Understanding the producing method and knowing what to look for allows you to make the best choice. Focus on satisfaction, compare suppliers, and never hesitate to ask questions before buying. Following those recommendations, you can invest in dependable lock housing that meets your wishes.

Start your search today and pick lock housing that offers safety and sturdiness!